TMT Plus is among the leading cPVC pipe fitting manufacturers in India and our cPVC pipes are made using the best material and deliver the most optimal plumbing performance. The features of these pipes make them a suitable and durable choice for various plumbing needs.

What makes cPVC pipes by TMT Plus the best in India is that they are manufactured to the highest standard. Our cPVC pipes are manufactured as per IS 15778 and as per ASTM D 2846. The pipes are available in SDR 11, SDR 13.5, SCH 40 and SCH 80, while the fittings are available in SDR 11. Our cPVC pipes and fittings range from 20mm to 50mm.

Technical Specifications

SDR-11

| Sizes(Inch) | Sizes(mm) |

|---|---|

| ¾“ | 20 |

| 1″ | 25 |

| 1¼“ | 32 |

| 1½“ | 40 |

| 2″ | 50 |

SDR-13.5

| Sizes(Inch) | Sizes(mm) |

|---|---|

| ¾“ | 20 |

| 1″ | 25 |

| 1¼“ | 32 |

| 1½“ | 40 |

| 2″ | 50 |

Fittings

SDR 11

SDR 13.5

Elbow 90

Coupler

Tee

Union

Male Threaded Adaptor

Female Threaded Adaptor

Reducer

Reducer Coupler

Reducer Bush

End Cap

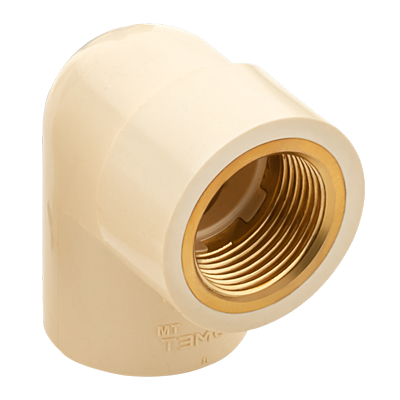

Elbow 45

Cross Tee

Socket Tank Nipple

Threaded Elbow

Transaction Bush U to C

Ball Valve

Step Over Band

Brass Elbow

Brass Tee

Brass MTA

Brass FTA

Features

- High Resistance: cPVC pipes have exceptional temperature resistance, making them suitable for both hot and cold water applications across various sectors. It can withstand hot temperatures up to 93°C and cold temperatures that are below freezing point.

- Low Thermal Conductivity: One feature that makes cPVC pipes unique is their low thermal conductivity. This allows it to effectively insulate the hot water temperature inside the pipe while protecting it from external temperature changes.

- Smooth Interior Surface: With these pipes, there is optimal fluid flow with minimal loss. This is possible because of their smooth inner surface, which minimizes friction. It also helps to ensure a high water flow rate and reduce the buildup of sediments.

- Corrosion Resistance: cPVC pipes provide superior resistance to rust or corrosion, like metal pipes. This feature makes it an excellent choice for plumbing use, especially where they may be exposed to acidic or alkaline substances found in water or industrial fluids.

- Low Thermal Expansion: cPVC pipes have insignificant thermal expansion and contraction, allowing them to retain their shape and size despite fluctuations in temperature. This stability reduces the risk of heat stress-related leaks or malfunctions, ensuring long-term reliability.

- Lightweight: When compared to traditional plumbing pipe materials, cPVC pipes are significantly lighter in weight. This makes them easier to handle and install while also reducing the costs of labour and shipping associated with them.

- High Impact Strength: The ability of these pipes to withstand high impacts ensures that they don’t get damaged during handling, transportation or installation. This feature also eliminates the need for costly repairs in the future, as they don’t break or crack easily.

- Fire Resistance: cPVC pipes are naturally flame-retardant and self-extinguishing, making them safer to use in both residential and commercial settings. In the case of a fire, cPVC pipes will not contribute to the spread of flames, allowing the fire to be contained while also protecting property and occupants.

- Chemical Resistance: cPVC pipes are suitable for industrial applications as they are highly resistant to a range of chemicals, like acids, salts, organic solvents, etc. This chemical resistance helps it maintain its strength when exposed to corrosive or aggressive fluids.

- Longevity: Maintaining these cPVC plumbing pipes can extend their life to more than 50 years. Proper maintenance eliminates the need for frequent repairs and saves money and time in the long run.

DO’s and DON’Ts

Do’s

- Cut pipes with a pipe cutter or a fine-tooth saw for smooth and even edges.

- Provide the pipes with adequate space and support to prevent stress or sagging.

- If installing yourself, follow the manufacturer’s guidelines for installation and maintenance.

- If your pipes are in freezing temperatures, properly insulate them to prevent damage.

- Use a CPVC-compatible solvent cement for strong and leak-proof joints.

Don’ts

- Don’t expose your CPVC pipes to direct sunlight for prolonged periods without UV protection.

- Don’t forget to test your pipes after installation.

- Don’t use your pipes for any purpose other than the assigned ones, i.e., transporting hot liquid and other plumbing needs.

- During installation, don’t ignore the proper alignment of the pipes.

- Don’t overburden the piping system, as it may lead to cracks.

Where You Can Use This Product?

Key Advantages of cPVC Pipes:

- 1. Long-lasting: cPVC pipes are made of plastic, so they don’t rust and are resistant to eroding substances, giving them a longer lifespan.

- 2. Robust: These pipes can withstand high water pressure, making them suitable for use as the main water supply line.

- 3. Ease of maintenance: cPVC pipes are lightweight and flexible, making them easy to handle and work with.

- 4. Temperature Tolerance: cPVC can handle extreme temperatures up to 93°F, making it suitable for transporting hot water.

- 5. Chemical Resistant: cPVC pipes are resistant to many household chemicals, enhancing their durability.

- 6. Self-Extinguishing: cPVC has a self-extinguishing function, meaning it does not catch fire when exposed to flames, improving safety.

FAQ

-

Is CPVC or uPVC better?

Though both have the same features, CPVC goes a notch above due to its high temperature resistance. If you are looking for pipes where hot water transportation is your primary concern, then you should definitely get CPVC pipes.

-

Are CPVC pipes safe for drinking water?

Yes. These pipes are created from high-quality, non-toxic materials, making them suitable for delivering drinking water.

-

Can these pipes be customised?

Yes. These pipes can be customised to meet the requirements of your project.

-

Are CPVC pipes expensive?

As compared to other materials, the initial cost may seem very expensive. However, these are suitable for many different applications and are very cost-effective, as they can last for decades without the need for repairs. These features make the price all the more worth it.

-

Are CPVC pipes safe?

Yes. These pipes are extremely safe as they are only sold after they go through 357+ checkpoints.

-

Is CPVC same as uPVC?

No. CPVC and uPVC are both different materials and a better extension of PVC. CPVC stands for Chlorinated Polyvinyl Chloride, while uPVC stands for Unplasticized Polyvinyl Chloride.

-

What range of pipes and fittings are available?

We offer cPVC pipes and fittings that range from 20mm to 50mm.

-

What applications can these pipes serve?

These pipes can be used for a range of applications, from residential buildings to public utilities, water heaters, indoor and outdoor plumbing and more.

-

Are our CPVC pipes and fittings certified for use in specific applications or standards?

Yes. TMT Plus CPVC pipes and fittings are certified for use in specific applications or standards. They are manufactured as per IS 15778 and ASTM D 2846.

Know More About Us

A supreme supplier of polymer products in India and a trusted company known for its durability and efficiency, TMT Plus has the better for you. Click below to find us!